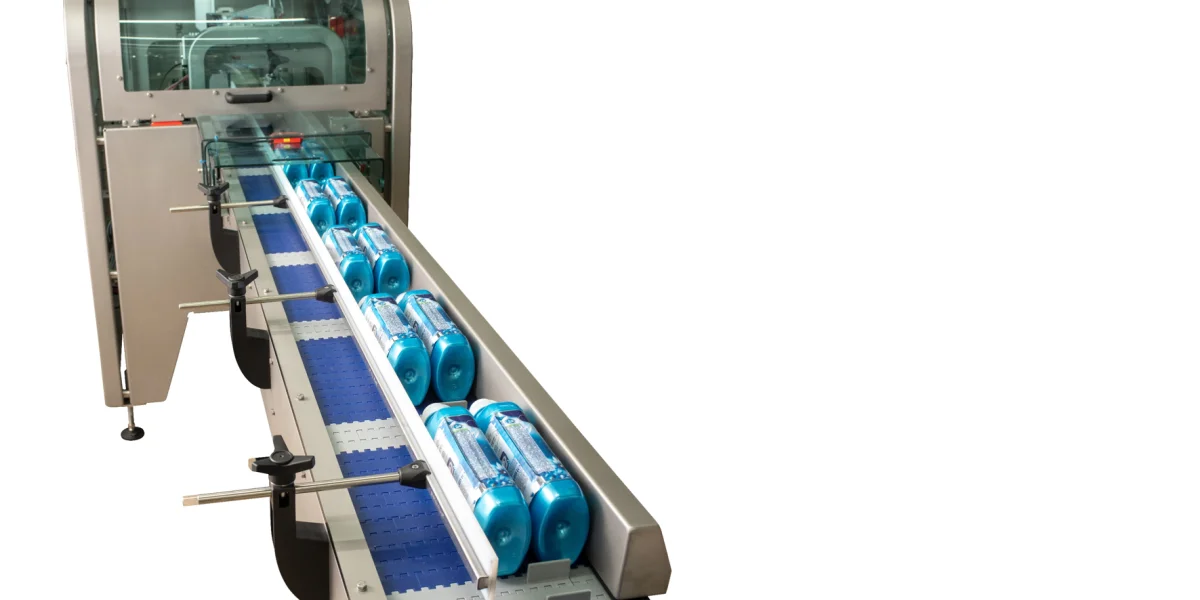

The new Bandall TRLS!

Flexible, modular and efficient bundling

Bandall has developed a new fully automatic bundling machine. This modular build machine is the answer to the common wish to automate, flexibility, and efficiency. Often due to staff shortages, at pre-packers, co-packers, and workshops. This way of bundling also saves on packaging material and energy use. Compared to shrink film, the reductions can be as much as 80%.

Ease of use

Adjustable

Both the guides of the infeed conveyor and the servo-driven pushers, with which the to be bundled products are brought to the banding arch, are easily adjustable.

Flexibility

Additionally, the banding arch itself is interchangeable in just a few actions. This is practical for possible maintenance, but also if the arch has to make space for a completely different band width. Even more flexibility is created by adding a printer. This allows for variable information to be printed onto the band during the banding process. This variable and flexible way of communicating saves on material costs, regardless of whether the banding material is paper or film. In addition, no excess material ends up as waste.

Renewed line

The new TRLS is a part of a completely renewed line of fully automatic banding machines. The innovations can be attributed to a number of details in the field of speed, user-friendliness, robustness, and flexibility.